How do I prepare my forklift for winter?

You don’t have to be a meteorologist or a Game of Thrones fan to know that Winter is coming. That nip in the air and the falling leaves should be enough to tell you that it’s time to prepare your forklift for Winter weather.

It’s something you might not even think about, but the fact is your forklift is every bit susceptible...

Read More

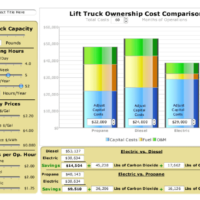

Pros & Cons: electric, propane, and diesel Forklifts

The decision to use an electric, LP or diesel forklift is determined by the application, run-time requirements, number of shifts, and environment of your company. For assistance in making that decision, here are some advantages and disadvantages of each:

Electric Forklift Advantages

Zero tailpipe emissions = safer work environment

...

Read More

Tips to Keep Engines Cool

Rising temperatures increase the potential for damage to your material handling equipment. You may experience engine wear at a higher rate, parts failures, and more maintenance expenses - which can all be avoided by taking a few precautions:

1. Replace work belts - they'll cause overheating

2. Coolant - check it and replace it regularly

3....

Read More

Forklift Maintenance for Safe Operation

In the material handling industry, many people use the terms 'preventative' and 'routine' interchangeable when in fact they are worlds apart. Everyone needs to know the difference.

The definition of routine maintenance is simple, small-scale activities (usually requiring only minimal skills or training) associated with regular (daily, weekly,...

Read More

Prepping equipment for winter

Making sure your forklift is ready for the cold ahead is similar to everyday maintenance, but you'll notice there are some more detailed items to check:

All safety equipment is functioning properly

Welds are not broken

Tires are full of air and are not missing any chunks

No visible leaks

Gauges are functioning properly

Chains and...

Read More

Keep equipment from overheating this summer

Rising temperatures increase the potential for damage to your material handling equipment. You might experience engine wear at a higher rate, parts failures, and more maintenance expenses - which can all be avoided by taking a few precautions, assuming you are conducting regular inspections.

1. Replace worn belts - belt failure can cause...

Read More

Best (small) Fit for the Warehouse

Move with efficiency...

Having the right tools in a distribution center, warehouse - whatever you call it- is essential to utilize best practices.

One way to increase efficiency and productivity is to keep up with the technology when it comes to your material handling equipment. Something that can easily be trained to use, maneuverable in...

Read More

Is your forklift the best fit for the warehouse?

A forklift is an important piece of equipment for any warehouse to have, but what type of forklift is the best?

According to the U.S. Occupational Safety and Health Administration (OSHA), there are seven classifications of forklifts, categorized as Class I – VII. Class I forklifts or electric motor rider trucks; Class II, which are electric...

Read More

Enhance productivity with reliable forklift accessories

When you incorporate accessories into your forklifts on the job, you get twice the power, with increased efficiency and versatility. Boost the usability of your most useful factory or warehouse machine — the mighty forklift — to transform its abilities from just a standard lift truck. Not only do you save time with more efficient operations,...

Read More

What does OSHA say about forklift attachments?

Operators must be trained in the proper use of attachments because they alter the performance of the forklift. Attachments affect the truck's performance by changing its center of gravity, visibility, and capacity. These are the federal OSHA regulations and descriptions of forklift attachment installation and use:

Common attachments:

...

Read More